How to make filter? 9

The filter, also known as the mouthpiece, is essentially a material used to filter smoke and reduce harmful substances.

Currently, the vast majority of cigarettes sold on the market are equipped with filters.

Globally, mainstream filter materials are divided into two types: polypropylene and acetate fiber.

Polypropylene filter rods are formed and dried using cigarette-grade polypropylene tow and specialized water-based adhesive for filter rods.

Polypropylene is a safe and non-toxic macromolecular material commonly used in food packaging, while the specialized water-based adhesive for filter rods typically consists of water-emplaced polyacrylate polymers or copolymers.

These adhesives are safe, non-toxic, and biocompatible, making them widely utilized high-molecular materials in the pharmaceutical and medical industries.

Polypropylene filter rods exhibit comparable adsorption and filtration efficiency for substances such as tar, nicotine, and carbon monoxide in cigarette smoke to cellulose acetate filter rods.

However, due to the inert nature of polypropylene material, they slightly lag in taste compared to traditional diacetyl fiber filter rods, making them predominantly used in low-end cigarettes. This does not imply they are unsafe.

As of 2023, polypropylene materials are gradually being phased out of the Chinese market due to unstable resistance and insufficient environmental performance.

In 1960, the first specialized filter was introduced—a binary one composed of cellulose acetate and Myria paper materials.

For 50 years since the introduction of cigarette filters(CF), cellulose acetate has held a prominent position, serving as the most unconventional material in the production cycle—even for the notoriously conservative tobacco industry.

Undoubtedly, cellulose acetate has become a widely accepted mechanical filter for both low-tar and high-tar cigarette consumers.1

Cellulose diacetate, also known as cellulose diacetate filament yarn, has the CAS number 9035-69-2 and the chemical formula C₂H₄O₂.

It is a cellulose derivative produced through the acetylation of natural cellulose. This material exhibits thermoplastic resin properties and belongs to a lower degree of esterification in the cellulose acetate category.

Its dyeing performance and moisture absorption rate surpass those of cellulose triacetate. The material is manufactured through the esterification of cellulose with acetic anhydride under the action of a catalyst, involving processes such as dissolution, filtration, and spinning.

Primarily used as the core material for CF, it selectively adsorbs tar and harmful particles from smoke while preserving the nicotine flavor.

In the textile industry, it is applied to composite filament products like suit linings and sportswear.

In plastic processing, it is utilized for eyeglass frames, tool handles, and biodegradable materials. Additionally, it finds applications in the pharmaceutical industry for filtration equipment.2

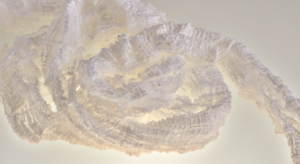

Cellulose acetate tow (referred to as filament) is a food-grade precision filtration material primarily used in the production of CF.

It is made from natural cellulose sources such as wood pulp or cotton pulp, which is processed into cellulose diacetate film through acetylation.

The material is then subjected to dissolution, filtration, spinning, crimping, and drying to produce the final product. 3

Cellulose acetate tow is a regenerated cellulose fiber characterized by excellent moisture absorption and adsorption properties.

The cross-sectional morphology of individual filaments is Y-shaped, and the large specific surface area of the fibers enables effective adsorption and retention of harmful components in cigarette smoke.4

As early as 2013, tobacco companies pioneered the use of polylactic acid filaments in CF, followed by Marlboro, which adopted polylactic acid as the production standard for low-tar CF.

CF made from polylactic acid (PLA) fibers possess four notable characteristics:

- Derived from annual plants, they are more cost-effective and readily available than wood, resulting in lower production costs.

- Fully biodegradable, they are a true “green” product.

- Manufactured using melt spinning technology to create filament bundles, which reduces processing costs and minimizes environmental pollution.

- Their polar molecular structure enables the adsorption and removal of harmful components in cigarette smoke.

Therefore, the adoption of PLA filters will bring significant transformation to the CF material industry.

Polylactic acid fiber is gradually gaining market share as a substitute for triacetate fiber.